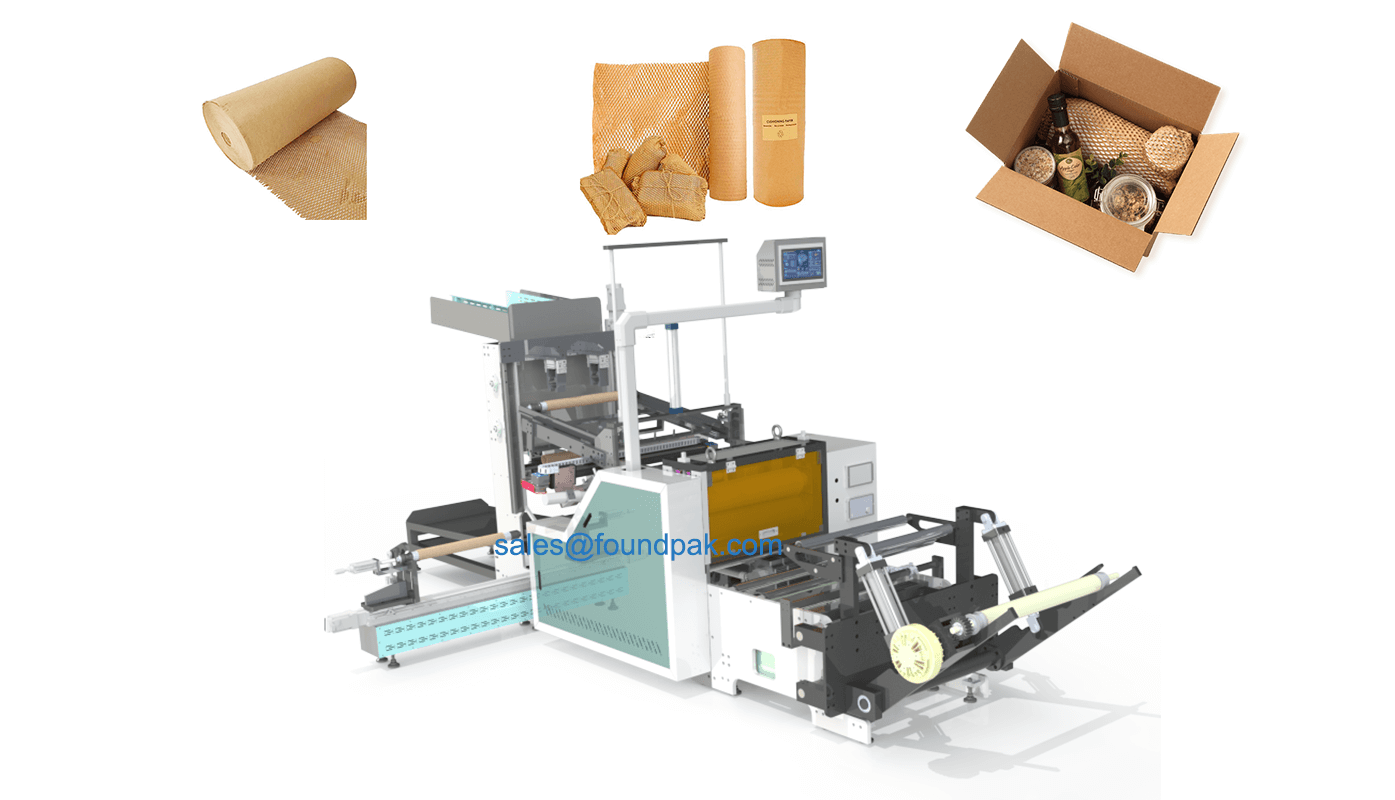

Fully Automatic Kraft Packaging Production Line Honeycomb Paper Making Machine

Fully automatic honeycomb paper making machine is produced with fully automatic mechanism to increase efficiency to produce cross-cut honeycomb paper to make lightweight, durable and recyclable honeycomb paper packaging material.

1. Fully automated, automatic and efficient

2. Suitable for cross-cut honeycomb paper

3. Equipped with emergency stop button

4. Adjust the speed and parameters through the control panel

5. Automatic cutting and stacking

6. Simple operation and high production efficiency

7.100%recyclable and biodegradable packaging

- Found

- Xiamen

- Information

- Video

Machine Introduction

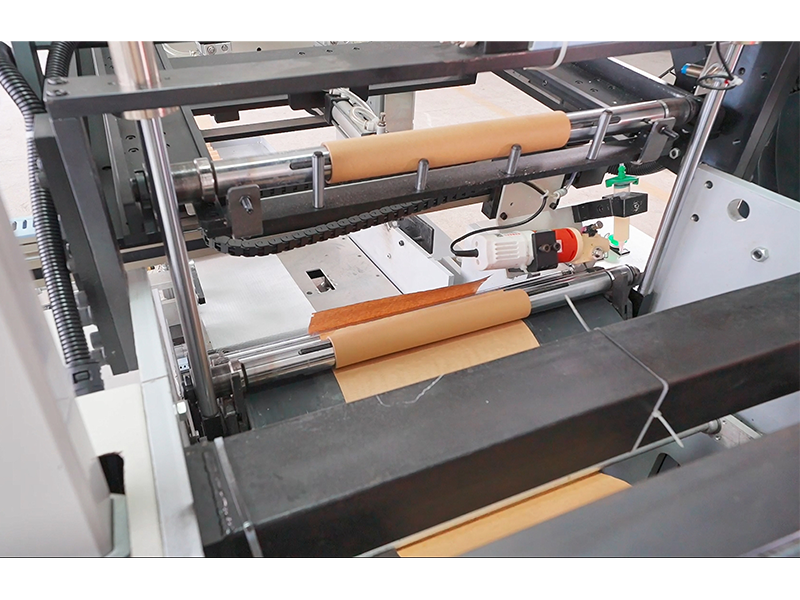

The fully automatic honeycomb paper making machine is a high-end manufacturing equipment that combines modern precision machinery, automated control and recyclable kraft paper processing technology.

It uses advanced continuous production technology to transform single-plane paper into high-strength cardboard with a three-dimensional honeycomb structure through continuous stretching, bonding, shaping, drying, cutting and other steps. During this process, the paper is cleverly shaped into countless connected hexagonal cells, forming a structure similar to a honeycomb in nature, hence the name "honeycomb paper".

Moreover, the machine can realize automatic control of winding and unwinding. It also has an automatic feeding device (1.5KW hydraulic system) and an automatic correction system to ensure neat edges of finished products and stable and reliable machine operation. The machine can be customized with color, logo or other brands, and the source factory provides a 1-year warranty and product operation videos and maintenance.

Product Specification

| 1 | Item | Full Automatic Honeycomb Paper Making Machine |

| 2 | MOQ | Support 1 piece delivery |

| 3 | Logo & Color | Accept logo and color customization |

| 4 | Warranty | 1-year |

| 5 | Effective Width Of Die-cutting Stick) | 550mm |

| 6 | Effective Unwind Width | 540mm |

| 7 | Die-cutting Roll | Φ240*600(Helical Tooth) |

| 8 | Die Cutting Bottom Roller | Φ240*600(alloy steel+main servo drive) |

| 9 | Wrap-Up | 300 Roller Friction Winding |

| 10 | Automatic Feeding Device | 1.5KW Hydraulic System |

| 11 | Automatic Deviation Correction System | 110 Synchronous Electromechanical Cylinder Correction |

| 12 | Parameters | Machine Size:L*W*H (4840*2288*2100)Speed:5-280m/minPower:6KMVoltage:380V/50HZ |

| 13 | Weight: | 2500KG |

| 14 | Automatic Tube Loading Device | (Automatic loading of paper tube + automatic loading of inflatable shaft + automatic pumping + automatic placement of inflatable shaft + automatic winding of inflatable shaft + automatic placement of finished product) |

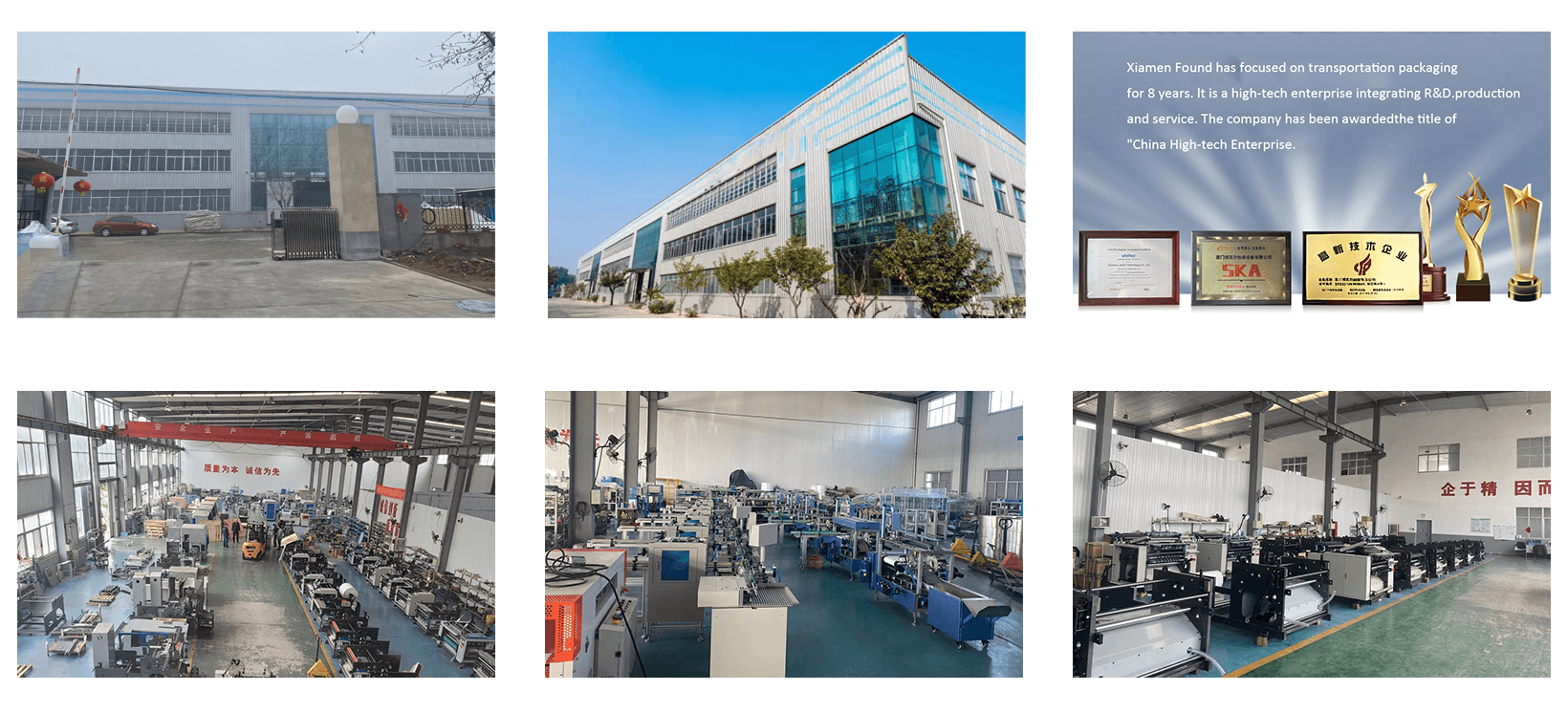

Our Factory

Precise sales, think what you think

By inspecting the global paper bag production status, comprehensively considering the suggestions of sustainable packaging industry, according to the actual needs of different customers, we design and produce a variety of configuration models, allowing customers to choose flexibly.

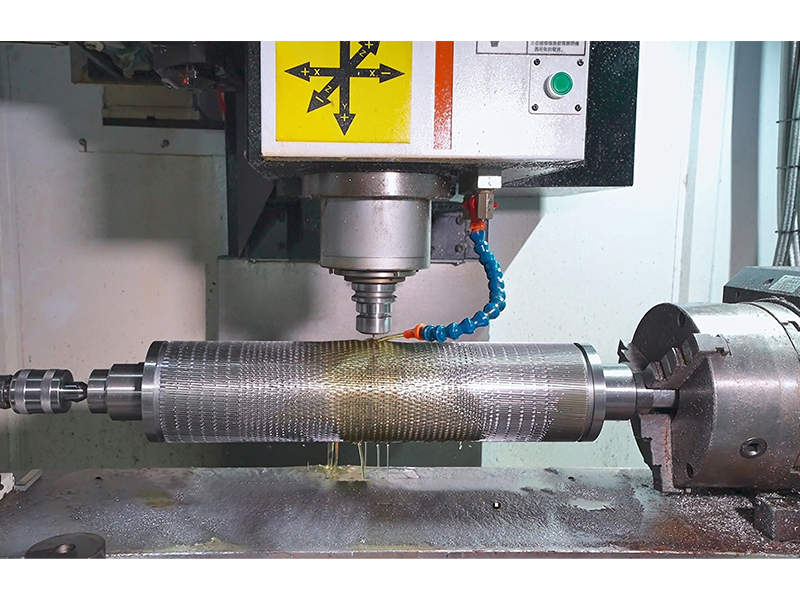

Excellent R& D management

We have an excellent R& D design team and excellent management talents in the packaging machine industry. We fully understand the actual needs of the packaging industry, ensuring that every piece of equipment we manufacture can be affirmed by customers and create greater benefits.

After-sale guarantee

Provide customers with comprehensive and timely after-sales service and a sense of service in the end.

Certifications